Energy Saving Ordinance

FACADES according to EnEV 2016 - GEG 2019

Heat loss minimization - use of aluminium? Using systems supplied by Innofixx equipment GmbH, these are no longer problems, now or in future!

Heat loss minimization - use of aluminium?

Using systems supplied by Innofixx equipment GmbH, these are no longer problems, now or in future!

HTP-Unit (high temperature plate = thermal decoupling +

wall bracket)

RTP-Unit (reduced temperature plate = thermal decoupling + wall bracket)

SFD-Stainless steel dowels for distance mounting

SLD-Stainless steel dowels for mounting weather shells

Heat losses via building envelopes play a central role in the total energy consumption of a building. Due to the more stringent requirements of the EnEV 2016 (Energy Saving Ordinance), EEWärmeG (Renewable Energy Heat Act) and the new GEG 2019 (Building Energy Act) building work which complies with the law will not get any easier in the future.

HTP

Our HTP unit

with up to 30% better (Chi) values* compared to other commercially available thermal decoupling systems is being successfully deployed with aluminium wall consoles and an aluminium substructure to fulfil EnEV 2016. In conjunction with the hot-dip galvanized sheet steel console (which was awarded the Innovation Award 2019), our HTP unit has been successfully tested by the Passive House Institute Darmstadt and declared a certified component. Therefore its deployment in the construction of passive houses is also possible (see the Passive House certificate).

RTP

Our RTP unit

is an advanced development of the HTP. This RTP will revolutionize the market for thermal decoupling systems, starting in the spring of 2020. The improvement to the RTP will provide up to 44% better (Chi) values* compared to all commercially available thermal decoupling systems.

* punctual heat transfer coefficient

With our systems, builders, planners and installers

are well positioned today to meet the challenges of the expected GEG 2019.

* punctual heat transfer coefficient

INNOFIXX DOWEL

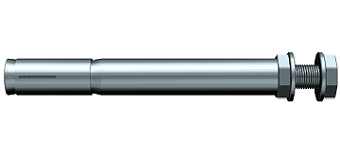

Stainless Steel (A2-A4) INNOFIXX SFD Dowel

The stainless steel INNOFIXX SFD dowel: is a patented system and has been assessed as a design free of thermal bridges (the 2-3% of isolated point thermal bridges can be neglected according to the current EnEV 2016) and in addition allows execution in A1 quality, hence construction of passive houses is also possible.

With this distance dowel, installation can be carried out through existing ETICS layers or concrete weather shells, without the need to remove the existing material.

The dowel simultaneously absorbs lateral,tensile and compression forces and transfers them safely into the load-bearing structure. Applications include the anchoring a hole range of add-on fixtures e.g. flues, balconies,canopies, awnings, advertising, etc.

Stainless Steel (A2-A4) INNOFIXX SLD Dowel

The stainless steel (A2-A4) INNOFIXX SLD dowel will be used in the area of facade anchoring. It unique feature is the simultaneous absorption of lateral,tensile and compression forces (anchoring concrete weather shells for A1-constructions)

European Technical Assessment 2020/21.

European Technical Assessment 2020/21.

The energy assessment is positive. As the isotherm pattern shows, the new INNOFIXX heavy-duty facade dowel produces significantly reduced thermal brdiges in comparision to trandtional dowels. The poiunt of penentration of a single dowel in the substrate is significantly smaller than the anchoring surface area of otehr aluminium facade systems.

Copyright © Alle Rechte vorbehalten.