Dowel fasterners

INNOFIXX energy efficient systemsOur distance-bridging and heavy duty dowels

How to reduce heat loss in a building facade?

Thermal efficiency is high on the agenda for Project Managers and Architects and yet metal substructures still account for up to 50% heat loss in a ventilated facade.

With INNOFIXX’s innovative solutions that all changes.

At INNOFIXX, we are committed to providing you with the most economical system to meet your needs. This includes a substructure optimized in terms of U-value and statics.

With INNOFIXX’s innovative solutions that all changes.

At INNOFIXX, we are committed to providing you with the most economical system to meet your needs. This includes a substructure optimized in terms of U-value and statics.

INNOFIXX DOWEL

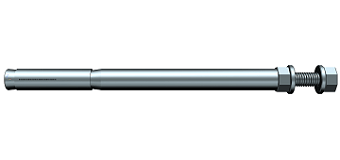

Stainless Steel (A2-A4) INNOFIXX SFD Dowel

The stainless steel INNOFIXX SFD dowel: is a patented system and has been assessed as a design free of thermal bridges (the 2-3% of isolated point thermal bridges can be neglected according to the current EnEV 2016) and in addition allows execution in A1 quality, hence construction of passive houses is also possible.

With this distance dowel, installation can be carried out through existing ETICS layers or concrete weather shells, without the need to remove the existing material.

The dowel simultaneously absorbs lateral,tensile and compressive fources and transfers them safely intothe load-bearing structure. Applications include the anchoring a hole range of add-on fixtures e.g. flues, balconies,canopies, awnings, advertising, etc.

With this distance dowel, installation can be carried out through existing ETICS layers or concrete weather shells, without the need to remove the existing material.

The dowel simultaneously absorbs lateral,tensile and compressive fources and transfers them safely intothe load-bearing structure. Applications include the anchoring a hole range of add-on fixtures e.g. flues, balconies,canopies, awnings, advertising, etc.

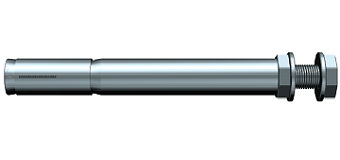

Stainless Steel (A2-A4) INNOFIXX SLD Dowel

Refurbishing older buildings without the destruction of the existing wall.

The refurbishment of facades with old heat insulation composite systems or the deployment of energy modernization and renovation, is simplified with the usage of INNOFIXX heavy duty dowels. With existing sub-structures the heat insulation composite system has to be demolished whilst innovative INNOFIXX heavy duty dowels would be anchored by passing through the existing heat insulation composite system. This feature makes any refurbishment very easy. The raw plug/dowels can be used to fixate conventional sub structures and, because of the anchoring used, the structure will have lower heat bridges compared to conventional sub-structures usage. INNOFIXX heavy duty dowels can sustain lateral, transverse and tensile loads and transfers those loads over larger distances in a secure way.

The INNOFIXX dowel simultaneously absorbs lateral, transverse and tensile loads and transfers them safely into the load-bearing structure.

In the case of modernization this means new facade elements can be mounted on existing sub-structures without problems, when using the right size of INNOFIXX heavy duty raw plugs.

INNOFIXX FOR DISTANCE BRIDGING

The new fastener innovation for distance-bridging on facades and roofs.

Heavy duty refurbishment dowel for re-anchoring of concrete weather shells. Application for approval in each individual case required. The INNOFIXX dowel simultaneously absorbs lateral, transverse and tensile loads and transfers them safely into the load-bearing structure. Can be used to fix loads such as canopies, balconies, advertising.

Reduce heat-loss.

From an energy perspective, the INNOFIXX dowel is in compliance with the energy saving ordinance (EnEV). Tests with respect to the optimum isotherm line showed that the INNOFIXX

dowel has superior qualities in respect to much lower head bridges compared to conventional fixation systems. Those qualities are based on the high quality stainless steel used to produce the INNOFIXX raw plug as compared to conventional

aluminum structures. The penetration point within the sub-structure of a single raw plug is much lower compared to the anchoring space that is required by conventional aluminum

based facade constructions. It has been proven through calculations that the inner wall temperature with conventional raw

plugs is 1.4 degrees Celsius higher compared when using the INNOFIXX dowel.

dowel has superior qualities in respect to much lower head bridges compared to conventional fixation systems. Those qualities are based on the high quality stainless steel used to produce the INNOFIXX raw plug as compared to conventional

aluminum structures. The penetration point within the sub-structure of a single raw plug is much lower compared to the anchoring space that is required by conventional aluminum

based facade constructions. It has been proven through calculations that the inner wall temperature with conventional raw

plugs is 1.4 degrees Celsius higher compared when using the INNOFIXX dowel.

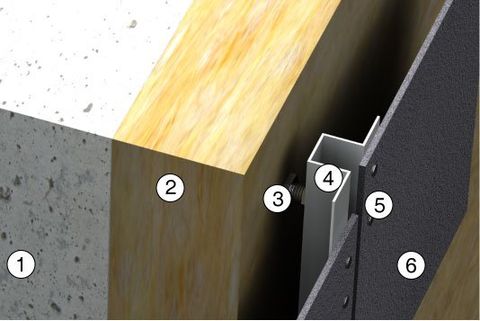

New-build using distance-bridging, sleeve anchor dowels, suitable for concrete

Reduced thermal bridges using our patented distance-bridging sleeve anchors dowels. All loads are transferred into the building´s load-bearing structure.

Cladding-screwed, riveted or adhesive-bonded

Example with cladding and a vertically installed aluminum sub-structure.

Example with cladding and a vertically installed aluminum sub-structure.

- Load-bearing concrete

- New thermal insulation

- Heavy-duty, V4a stainless steel sleeve anchor dowel ø 12,16 or 20 mm

- Aluminum top-hat section (Omega profile)

- Rivets/Screws/Adhesives

- Cladding

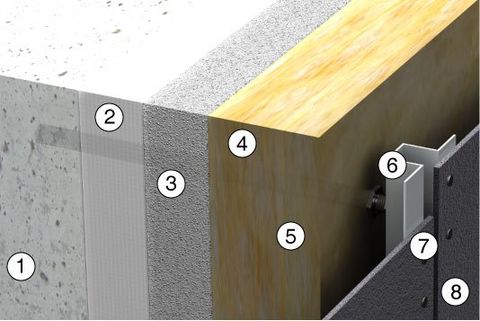

Refurbishment of building with existing weather shell system

Reduced thermal bridges using our patented distance-bridging sleeve anchors dowels. All loads are transferred into the building´s load-bearing structure.

Cladding-screwed, riveted or adhesive-bonded

Example with cladding and a vertically installed aluminum sub-structure.

Cladding-screwed, riveted or adhesive-bonded

Example with cladding and a vertically installed aluminum sub-structure.

- Load-bearing concrete

- Old thermal insulation between load-bearing concrete and weather shell system

- old render/plaster coat

- Heavy-duty, V4a stainless steel sleeve anchor dowel ø 12,16 or 20 mm

- New thermal insulation

- Aluminum top-hat section (Omega profile)

- Cladding

- Rivets/Screws/Adhesives

Renovation of a building with ETICS facade

Reduced thermal bridges using our patented distance-bridging sleeve anchors dowels. All loads are transferred into the building´s load-bearing structure.

Cladding-screwed, riveted or adhesive-bonded

Example with cladding and a vertically installed aluminum sub-structure.

Cladding-screwed, riveted or adhesive-bonded

Example with cladding and a vertically installed aluminum sub-structure.

- Load-bearing concrete

- Old ETIC system

- old render/plaster coat

- Heavy-duty, V4a stainless steel sleeve anchor dowel ø 12,16 or 20 mm

- New thermal insulation

- Aluminum top-hat section (Omega profile)

- Cladding

- Rivets/Screws/Adhesives

INNOFIXX offers the right solution to bridge any distance

The INNOFIXX dowel simultaneously absorbs lateral, transverse and tensile loads and transfers them safely into the load-bearing structure. Distances up to 300mm and more can be bridged. The INNOFIXX dowel is officially approved by the German Institute for Building Technology (DIBt).

A suitable INNOFIXX dowel is available for every distance-bridging installation application. The heavy-duty sleeve outer diameter ranges from 15 - 51mm and has a wall thickness of 2-6mm. Distances up to 300mm and more can be bridged.

Advantages

Applications

Copyright © Alle Rechte vorbehalten.